Our Quick Ship program lets you experience the maintain-in-place benefits of our EZstrip™ pump faster than ever.

Enjoy the quick deliverable solution that ensures you’ll have the products you need on-time and on-budget. Our most common EZstrip™ options are available to ship in as little as one to two weeks. From engineering consultation and repairs to spare parts and training, you can rely on us for quick and effective support throughout the entire life of your project,

Moyno™ pumps deliver superior pumping and solids reduction performance with longer service life. For highly abrasives or corrosive applications Moyno™ pumps use their patented Ultra shield on their rotors for peak performance under these brutal conditions. Moyno™ pumps are not only for abrasives or corrosive applications they have been successfully used in the waste water treatment industry, food, sanitary & many other industries. In brief Moyno™ also offers mag drive pumps, General utility, dosing & sanitary pumps.

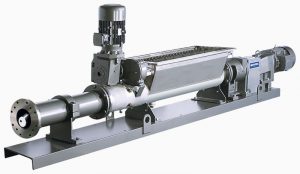

Moyno™ New EZstrip™ Transfer Pump

The New Ezstrip™

For the newest iteration of our EZstrip™ maintain-in-place progressing cavity pump, we designed new features to make maintenance even more user friendly than before. In addition to our patented split suction chamber, we’ve removed the tie bars, designed a new positive torque split coupling rod and added a captive support foot. That means faster, easier maintenance for you without sacrificing any pumping performance.

Our EZstrip™ progressing cavity pumps offer an innovative solution for materials transfer and sludge conditioning to keep your operations flowing – safely and efficiently. Whether you’re managing a treatment facility in municipal wastewater, mining or a chemical process industry, we’re ready to help you stay productive

NOV 2000WB Pumps – CLOSE COUPLED DESIGN

The NOV 2000 pumps close coupled pump is specifically designed for lower pressure, lower flow applications that do not require the full features and benefits of the 2000G1 pump. The 2000WB model features a traditional close coupled design where the loads are supported by the gear reducer bearings. This design reduces the overall stress that can occur in the gear reducer.

The 2000WB is specifically designed for applications that require the transfer of highly viscous fluids and solids where a close coupled configuration is preferred, but the robustness of a gear joint is desired.

Features and Benefits

- Traditional close coupled design

- No shaft bearings

- Thrust and radial loads supported by the bearings in the gear reducer

Typical Applications

- Municipal Wastewater Treatment

- Pulp and Paper

- Oil and Gas

- Food Waste

- Petrochemical

NOV 2000WA Pumps – CLOSE COUPLED DESIGN

The NOV 2000 pumps close coupled pump is specifically designed for lower pressure, lower flow applications that do not require the full features and benefits of the 2000G1 pump. The 2000WA features a close coupled design that has integral bearings that support the radial thrust loads that can be seen at the rotor/stator. This design reduces the overall stress that can occur in the gear reducer.

The 2000WA is specifically designed for applications that require the transfer of highly viscous fluids and solids where a close coupled configuration is preferred, but the robustness of a gear joint is desired.

Features and Benefits

- Close coupled bearing housing design

- Bearings integral to adapter housing

- Uses standard size / keyed gear reducer shaft

- Sealed gear-type universal joint drive train

Typical Applications

- Municipal Wastewater Treatment

- Pulp and Paper

- Oil and Gas

- Food Waste

- Petrochemical

NOV G1 – FLANGED DESIGN

High-performance NOV 2000 Pumps offer low maintenance, minimal downtime and long service life for low total cost of ownership.

- Fluid Type: Broad range of viscosities and solids

- Fluid Supply: Via standard pipe

- Benefits: Best value for majority of applications

Typical Applications

- Oil

- Polymers

- Municipal sludge to 10% solids

- Titanium Dioxide

- Paper coatings

- Mining Slurries

NOV G2 Pumps – SINGLE AUGER FEED

High-performance 2000 Pumps offer low maintenance, minimal downtime and long service life for low total cost of ownership.

- Fluid Type: Viscosity and solids where open inlet is required

- Fluid Supply:

- Via wide open-throats and chutes

- Capable of varying length to match wide feed areas from centrifuges and 1, 1.5, and 2-meter length belt filter presses

- Benefits:

- Single auger feed mechanism to stuff product into the pump elements for increased fill efficiency

- Wide open-throat minimizes plugging that could occur in a standard inlet

Typical Applications

- Heavy clay slurries

- Gypsum

- Grout

- Grape must

- Municipal GBT sludge

- Municipal sludge to 15% solids

- Thick industrial sludges

NOV G3 Pumps – BRIDGE BREAKER

High-performance 2000 Pumps offer low maintenance, minimal downtime and long service life for low total cost of ownership.

- Fluid Type: Medium- to high-viscosity and solids where product bridging is a concer

- Fluid Supply:

- Via wide open-throats and chutes

- Capable of varying length to match wide feed areas from centrifuges and 1, 1.5, and 2-meter length belt filter presses

Benefits

- Independently driven Moyno™ bridge breaker has the flexibility to operate at different RPM from the pump

- Single auger feed mechanism to stuff product into the pump elements for increased fill efficiency

- Wide open-throat minimizes plugging that could occur in a standard inlet

Typical Applications

- Pharmaceutical pastes

- Heavy petroleum sludges

- Plasticizers

- Municipal sludge in excess of 30% solids

- Paper stock in excess of 12% solids

NOV G4 Pumps – 45 INLET DESIGN

The high-efficiency G4 progressing cavity pump’s 45°inlet lowers friction loss and provides for gentler handling of the product.

- Fluid Type: High solids

Benefits

- Universal joint that is out of the fluid flow path for unobstructed flow to the pump cavity inlet

- Lower overall system pressure

- Constant, non-pulsating flow imparts less stress on piping machinery and drive systems

- Patented auger feed on the rotor head smoothly stuffs product directly into the cavity without obstruction

- Rotor configuration is designed to enhance flow of high solids content materials and optimize volumetric efficiency

Typical Applications

- Pharmaceutical pastes

- Heavy petroleum sludges

- Plasticizers

- Municipal sludge in excess of 30% solids

- Paper stock in excess of 12% solids

NOV 2000 Pumps – HS SYSTEM

The 2000 HS System combines high pump efficiency with low discharge pressure to provide unmatched performance in high solids sludge cake transfer. Compared to hydraulically driven, piston ram type pumps and open conveyors, the 2000 HS System requires a much lower capital investment, lower operating costs and less maintenance.

- Fluid Type: High-viscosity and high-solids

- Fluid Supply:

- Via suction hopper of Twin Screw Feeder (TSF) and chutes

- Capable of varying TSF length to match wide feed areas from centrifuges and 1 through 2-meter length belt filter presses

Benefits (Twin Screw Feeder)

- Capable of varying auger sizes without changing pump arrangement to match the width of the TSF opening to the drop zone

- Concentric rotation in a close tolerance pressure tube allows the TSF to generate positive stuffing pressure to the pump inlet (normally between 10 to 30 PSI at the pump inlet)

- TSF can be run at separate RPM from the pump, allowing control over the amount of stuffing pressure

- Close tolerance to sidewalls eliminates product ledge where bridging can gain a foothold

- Sidewalls are completely vertical into the augers, which does not allow product to bridge

- Intermeshing augers provide self-cleaning action so product will not stick to the augers and fill in the flights

- Dual augers counter-rotate to create a pull-down effect with the product

Typical Applications

Benefits (G4 Pump)

- Municipal sludge from 15% to over 50% solids

- Non-flowable products

- Calcium Carbonate

- Magnesium Hydroxide paste

- Battery paste

- Spent grain

- Cellulose fiber

- Universal joint is out of flow path for unobstructed flow to pump cavity inlet

- Wide sweep pump inlet to lower friction loss

- Patented auger feed on rotor head stuffs product directly into the cavity without obstruction

NOV Compact C Pumps

Compact C Pumps delivers reliable performance to the maximum duty requirements of your application in a compact package. Features include suction lift capability up to 28 feet, positive displacement for process control, and variable speed for accurate dosing.

Features

- Available in cast iron or stainless steel, with a choice of rotor and stator materials

- High pressure / long haul pumping, eliminating the need for a series of pumps when pumping over long distances or with high head requirements

- Low running speeds – ideal for abrasive applications

- The pump can be supplied with a square inlet and conveyor to assist viscous slurries into the pumping element

- Inspection cover available for applications where rag content is a problem

- Gentle pumping action minimizes shear and crush damage

- Available in standard geometry or extended pitch

Typical Applications

- Domestic and industrial effluents

- Sludge

- Milk curds, sauces, fruit juices

- Industrial chemicals

- Starch slurries

- Hydrated lime slurry

- Agriculture slurries

- Paper stocks

- Gypsum and silicate

- Coating clays

- Detergents

NOV MAG DRIVE PUMPS

Moyno™ pumps Mag Drive series are the first progressing cavity wobble stator pumps.

Features

- Patented, sealless technology provides zero leakage, preserving expensive fluids, eliminating hazardous work place conditions and protecting the environment

- No mechanical seals are used, eliminating costly repairs

- Pulsation-free, low shear pumping action maintains product integrity

- No vapor locking when handling gaseous, volatile liquids

- Skid mounted, turnkey systems are available for one-stop, hassle-free shopping, saving time and money

- Stator materials include FPM with optional Nitrile and EPDM; Titanium rotors are standard

- Materials of construction include PVC housings

- Various motor options available

- Four models from which to choose for application versatility

NOV GENERAL UTILITY PUMPS

Designed for use where low flow or transfer duties in both domestic and industrial applications are required, these self-priming pumps can achieve suction lifts up to 26 feet.

Features

- Progressing cavity pump principle ensures steady output pressure and non-pulsing flow with minimal slippage–a very useful feature when pumping heating oil to burner nozzles for example

- Smooth action and resilient rubber stator ensures quiet running–ideal for light industrial and domestic installations

- Simple design and easy dismantle

- An abrasion and chemical resistant stator for handling viscous liquids and random solids

- Available either bareshaft or coupled with a motor

- High quality stainless steel rotating parts

- Available as cast iron, stainless steel or engineered co-polymer bodies

NOV DOSING/METERING PUMPS

The dosing/metering pumps provide a smooth pumping action with no pulsation and very low shear. Ideal for either intermittent or continuous duties.

Features and Benefits

- Dust and water resistant; works well in dirty, wet environments

- .5 – 5 HP capability

- 10:1 speed range

- 1 or 3 phase

- Pressure capability is independent of speed

- No valves to clog, stick or vapor lock

- Low power consumption and operating costs

- Low shear pumping action

- Self-priming, high suction lift capability

- Handles abrasives, corrosives, solids in suspension and viscous fluid

- LED external displays are visibly and ergonomically user friendly

- Handles simple drive function commands to more demanding positioning controls

- IP55 and IP55/NEMA enclosures are standard

- 4-20mA input for feedback control

- UL and cUL listed and CD marked

- Compact and rugged design

NOV EZSTRIP™ TRANSFER PUMP

The EZstrip™ Transfer Pump provides a quick and easy way to disassemble, de-rag, and maintain a PC pump in place, reducing maintenance time by more than 93% for significant cost savings.

Features

- Patented split coupling allows full removal of the drive train in minutes with no electrical disconnection required

- Pre-assembled drive train available with 2-year warranty to allow faster reassembly time

- Suction and discharge ports remain connected to the pipe work

- Operational parameters are unaffected since design has no effect on flow and pressure

- Stainless steel cast components and fasteners provide corrosion resistance making them suitable for a variety of applications

- Low running speeds reduces wear for a longer working pump life; ideal for abrasive applications

NOV EZSTRIP™ CAKE PUMP

The EZstrip™ Cake Pump features a specially designed feed chamber that can easily be disconnected allowing access to the rotating assembly. The rotor can be separated from the conveyor allowing removal of the rotor and stator all within its own assembled length. This process can take as little as 6 minutes!

Features

- Quick and easy to maintain-in-place

- Reduced maintenance downtime and labor savings

- No need to disconnect suction and discharge pipework, even when removing the screw conveyor

- Detachable feed chamber supplied as standard

- Option of a separate bridge breaker mounted directly on top of the hopper to ensure optimum filling of the auger feed screw

- Large auger design as standard – ribbon auger available to assist blending/conveying of product into the pump

- Side inlet port allows addition of thin sludge for blending and can also be used for draining the pump

NOV L-FRAME PUMPS

For nearly 50 years, versatile L-Frame pumps have stood the test of time meeting thousands of application challenges with performance-enhancing, cost-saving features.

Performance Features

Features

- Non-pulsating

- Low shear, accurate, repeatable flow

- Pressures to 2,100 psi; capacities from .02 to 450 gpm

- Handles solids to 1″ in diameter

- Viscosities to 1,000,000 cps

- Low total cost of ownership

- Simple pin-type universal joint drive assembly for easy maintenance

- Open suction hopper and bridge breaker models available

- Variety of Ultra-Shield® rotor coatings and Ultra-Flex® stator elastomers

- Steady flow under wide NPSH variations

- Application versatility, modular design and wide selection of materials of construction

Typical Applications

- High-pressure water

- Pastes & gels

- Food, wastes & by-products

- Chemical feed & sampling

- Coolants & lubricants

NOV EPSILON/VERTICAL

The Epsilon Pump is a line of technically engineered progressing cavity pumps designed to give least whole life costs and reduced spares requirements.

The Epsilon Pump incorporates a PowerDrive™ transmission which eliminates the need for a double universal joint. This competitively priced pump is reliable and efficient when handling abrasive materials, high viscosity fluids, and high head applications.

Features

- Available in cast iron or stainless steel, with a choice of rotor and stator materials. Other materials available on request for difficult applications, i.e. super duplex stainless steel

- High pressure/long haul pumping eliminates the need for a series of pumps when pumping over long distances or with high head requirements

- Low running speeds ideal for abrasive applications

- Can be installed vertically or horizontally

- Available in standard geometry or extended pitch

- PowerDrive™ transmission eliminates wearing components

- Gentle pumping action minimizes shear and crush damage

- Inspection cover available for applications where rag content is a problem

Typical Applications

- Primary and secondary sludge

- Mineral processing

- Industrial chemicals, detergents,

- Polyethlene glycol

- Kaolin slurry, coating slurry

- Gypsum and silicate

- Paper stocks

- Milk curds, sauces, fruit juices

- Mine dewatering

- Natural and synthetic latex

- Cocoa butter

- Starches, liquiefied potato peel,

- Crude oil, hydraulic oil, waste oil

NOV Invisiq Pressure Sewer System

INVIZIQ™

The InviziQ™ Pressure Sewer System is a smarter alternative to conventional gravity sewage options. Rather than relying on gravity and a network of costly lift stations to transfer sewage, PSS utilizes reliable grinding and pumping technology to efficiently and responsibly move sewage to treatment facilities – no matter the terrain, slope, environmental sensitivity of the area or complex topography of the region.

InviziQ’s advanced technology and enhanced features deliver a new level of performance, durability and reliability over competitive systems. InviziQ offers Dry Well design, the first and only PSS alternative delivering clean access to the system motor and other working parts of the unit. In addition, network monitoring and control is built into the system and its monitoring system is the most robust in the market. Whether it’s replacing an existing infrastructure or helping develop underutilized areas, InviziQ is changing the way people think about sewer systems.

Features and Benefits

- Unique, clean dry well is sealed and tested to eliminate water or sewage intrusion

- Tank and piping are sealed and tested to reduce I&I to zero to not allow inflow or infiltration

- Leading edge, solid-state level sensor provides more reliability than traditional, mechanical float alternatives. Also resistant to corrosion and grease-build up. Transducer allows adjustment of ON/OFF/ALARM set points to maximize capacity.

- Robust grinder pump offers zero planned maintenance. The all stainless steel pump cartridge provides reliable performance.

- Cleanout/observation port is large enough to accommodate cleanout hose, so there is no need to remove dry well cover

- Standard TEFC pump motor located in dry well is out of sewage, unlike other vendors who offer expensive submersible motors

Typical Applications

- Domestic effluent

- Sewage transfer

NOV TRI-PHAZE Pump

The multiphase fluid produced from many oil and gas wells is composed of varying ratios of oil, water, gas and in many cases, small amounts of sand and paraffin. Traditional multiphase fluid transfer involves the use of separation equipment and compressors at the wellsite or satellite to separate the oil, water and gas. The gas can be flared off and the separated fluids are then transferred via multiple pipelines, barges or trucks to a central processing station.

An older well is likely to have a gas volume fraction (GVF) which has increased over the years causing production to become marginal. The costs to install, operate and maintain the traditional multiphase fluid transfer equipment may not be justified by the production from the well or field.

Recently, efforts have been made to develop pumps capable of handling multiphase fluids. However, results indicate that most types of pumps are restricted by their inability to automatically adjust to rapidly fluctuating gas-to-liquid ratios. They can’t handle sand or other solids in suspension or efficiently pump fluids with varying API gravities. Many have a tendency to emulsify the fluid making separation much more difficult.

Prompted by a market need for a more efficient multiphase fluid transfer solution, Moyno, Inc. developed the breakthrough Moyno Tri-Phaze® System. Its patented progressing cavity design effectively pumps oil, gas and water from the wellsite or satellite through a single pipeline to a remote processing station without degradation or emulsification of the fluids. It effectively transfers multiphase flows up to 80,000 BPD and differential pressures up to 1,350 psi.

The progressing cavity design consists of a single-threaded, external helix (rotor) turning within a double-threaded internal helix (stator). As the rotor turns within the stator, cavities are formed that progress from the suction to the discharge end of the pump. The fluid flows in a spiral path through the pump not far removed from a straight line. The resulting low shear pumping action will not emulsify the oil and water phases, therefore making separation easier at the processing station.

By significantly lowering wellhead pressures, the Moyno Tri-Phaze System has been proven to increase production of even marginal wells. Furthermore, it can handle high gas volume fractions, high sand percent, aromatics, changes in API gravity, and H2S gas.

Features

- Uses a small electric motor that operates at slower speeds

- The patented design handles high gas volume fractions without premature breakdown of the stator due to excessive heat build-up.

- When compared to a new battery installation for a new or exisiting formation, the Moyno Tri-Phaze System costs less to install, maintain and operate, and is environmentally friendly.

NOV MINE DEWATERING

Progressing cavity pump mine dewatering systems have been employed in the mining industry for over 30 years. This is a highly efficient, fully integrated pump package solution for reducing the total cost of a mine dewatering program. The pump is based on the Epsilon Pump’s PowerDrive™ transmission providing increase reliability with no wearing components between the drive end and the pumping element. This technology is backed by a 10 year warranty.

Features

- Halar coated PowerDrive™ transmission with 10 year warranty

- Standard 316 SS, hard chrome plated (HCP) rotor

- Heavy duty mine spec motors

- Unique gland arrangement which can offer up to three times the life on your drive shaft wear

- High-quality, graphite gland packing

- Purpose built bearing housing for arduous mining environments with lip seals, labyrinth rings and continuous greasing facility

- Stator is made of resilient, abrasion resistant, synthetic rubber

Typical Applications

- Mine dewatering

- Ground lime pastes

- Polyelectrolyte flocculent

- Coal slurries

- Strata control

- Grout pacing

- China clays

NOV EZSTRIP™ TR MUNCHER™

The latest addition to the EZstrip™ family is a range of grinders offering a competitive solution to solids grinding and sludge conditioning. The EZstrip™ TR Munchers™ all house the quick release access port allowing the cutter assembly to be maintained in place without removing the equipment, reducing maintenance time.

Features

- Quick release access port allows the cutter assembly to be maintained in-place without removing the equipment and therefore reduces maintenance time.

- Rotational speed produces high torque, resulting in lower operating power at 1.5 or 2.2kW, which are available with energy efficient motors.

- Lower cutter tip speeds dramatically reduce wear rates. Slow speeds also ensure low noise and vibration, and good abrasion resistance.

- Off-loading requirements for ‘on-stand’ tankering are matched by the Munchers capacity.

- Pull-back cutter stack allows removal without disturbing the pipeline.

NOV Series A Grinder

The reliable Series S Muncher is well proven in its ability to effectively macerate raw sewage, sludge, screenings, and industrial process flows. Available for pipeline of channel installations, the shaft speed of 85 rpm offers low cutter tip speeds and therefore dramatically reduces wear rates in comparison to high speed macerators.

The Series A Muncher can be packaged with Moyno’s pump to provide a highly effective macerating, screening, or pumping system.

Features

- Power savings, elimination of manual handling and associated transport costs, odor control, and automated operation are all achieved when installing Munchers to replace conventional screening systems to existing or proposed submersible pump stations

- ETOS cutters offer positive and effective solids grinding

- Optional high flow side rails allow higher capacities whilst reducing the possibility of solids passing through without being macerated – typically an increase in capacity of 40%

- Can be installed in an existing concrete channel or in a fabricated frame, complete with guide rails, into existing submersible pump stations as a simple and quick retrofit

- Each Muncher is supplied with a programmable logic controller (PLC) to protect the machine against damage and overloads

- Muncher can be supplied to comply with the ATEX Directive 94/9/EC

Typical Applications

- Protection of pumps to eliminate blockages

- Submersible pump protection

- Fine grinding of sewage and sludges

- Disintegration of extracted screenings

- Head of works maceration

- Industrial effluent maceration

- Mud contaminated drill cuttings

- Food products and waste

- Slaughterhouse waste

- Aircraft effluent

- Prison waste water maceration

NOV DISCAM Grinder

The Discam is a unique grinder and screen system, which offers a much more effective and low maintenance alternative to handling screenings than conventional systems.

With the ability to capture up to 95% of solids at 5mm or 9mm aperture sizes, this innovative solution combines a self-cleaning screen with a high torque grinder. No manual attendance or cleaning is required and disposal costs for handling debris extracted by traditional screening processes is eliminated.

The Discam is constructed using a series of shafts, two of which are fitted with interleaving cutters and spacers to give ‘positive displacement’ solids grinding, while the remaining shafts are fitted with overlapping and intermeshing discs.

Easily retrofitted into existing sewage pump stations or inlet works, as well as installed in new build facilities, this high performance package is suitable for almost any type of waste water facility.

Features

- Power savings, elimination of manual handling and associated transport costs, odor control and automated operation are all achieved when installing a Discam to replace conventional screening systems to existing or proposed submersible pump stations

- Intermeshing discs give a self-cleaning screen

- Grinder allows liquid to pass through the cutter stacks, filtering, trapping, and macerating the entrained solids

- Ability to remove up to 95% of solids at the given aperture sizes

- Lower cutter tip speeds dramatically reduce impact load

- Slow speeds also ensure low noise and vibration and good abrasion resistance

- Screening apertures at 5 and 9 mm available

- 1000mm, 1500mm and 2000mm channel depth options

Typical Applications

- Pump station screening

- Inlet works screening

NOV 500 SANITARY PUMPS

500 Sanitary Pumps offer low flows and high performance in a compact, cost-effective size. Made of food-grade 316 stainless steel to meet 3A sanitary standards, this versatile pump also features elastomers that satisfy FDA requirements.

Features and Benefits

- Accurate, repeatable, non-pulsating flow for shear-sensitive applications

- Application versatility, from clean, clear liquids, additives and flavorings to viscous and abrasive fluids

- Design simplicity and premium components for reduced maintenance and replacement

- Quick disassembly clamp for easy cleaning

- Bare Shaft and Close-Coupled models available

- Sanitary and cost-saving Hygienic models available

NOV AUGMENTOR Pumps

AugMentor® Pump Stuffer Ensures Reliable, Positive Feeding of High-Viscosity Materials

The AugMentor® Pump Stuffer handles high-viscosity materials otherwise unpumpable by conventional means. Materials in excess of 1,000,000 cps, such as cold processed meats and bakery dough, are easily fed by the AugMentor’s slow-speed, bottom-drive auger.

Features and Benefits

- The unique design of the AugMentor offers numerous performance enhancing features

- Low shear transfer with little smearing preserves product integrity

- Unobstructed, wide-open stuffer facilitates continuous positive feed of pumped material

- Hinged hopper permits easy clean-up and inspection

- 300 series stainless steel construction polished to a #4 finish for maximum corrosion resistance and cleaner sanitary surfaces

- Less costly to maintain than hydraulic feed systems

NOV CHOPPER HOPPER Pumps

Moyno™ has created a food products processor that combines solids reduction and transfer pumping into one efficient unit. The patented Chopper Hopper™ is a unique and aggressive solids reduction pumping system that reduces whole produce – papayas, pineapples, pumpkins or any other fruits or vegetables – into an easy to handle puree or mash.

The Chopper Hopper™ provides fast, simple and effective handling of waste by-products. Up to three stages of solids reduction are available for coarse, medium and fine particle size.

Features and Benefits

- Pump and grinding operation in a single, compact package

- Maximizes processing

- Large surge capacity hopper

- Easy disassembly of cutter shafts and pump internals

- Fast process times through three stages of solids reduction

- High flow rates

- Reduces overall cost of ownership

- Requires minimal maintenance

NOV SANITARY PUMPS

Low-shear, non-pulsating NOV Sanitary Pumps transfer shear-sensitive materials with a minimum of turbulence or stress.

NOV Sanitary Pumps – Features

- Mechanical seals standard

- Standard models meet 3A and BISSC sanitary requirements with no modifications

- Close-coupled and open throat models

NOV SANITARY HIGH PRESSURE PUMPS

The Sanitary High Pressure Pump features a rugged, field proven design modeled after the heavy-duty, 2000 Series Pump. Its low maintenance design and extended performance envelope make it ideal for handling high flow rates, high pressures and high viscosities.

The Sanitary High Pressure Pump’s low shear pumping action and large, internal cavities maintain product integrity when transferring particulate-laden fluids.

Features and Benefits

- Single drive train with pinned connections

- CIP design available

- Standard mechanical seal is not exposed to high pressure

- Low profile design

Moyno Pumps

-

Moyno 2000 Series

Industry Review

Moyno™ Pumps 2000 G4 series pump with ANSI inlet and the auger feed into the rotor-stator section. This is important when it comes to feeding your viscous materials into the pump. The 2000 series Moyno™ Pumps are used in the more demanding application and are very well received in the drywall mud manufacturing application .

What makes the Moyno™ pumps superior to their competitors in most cases is the quality of materials, workmanship, and the technology used in the drive end of the pump. The pump uses a gear joint verses the pin joints used by the competitors. The life of this drive end is far greater than the pin joint construction.

Sincerely,

Brent