Previously Featured Products

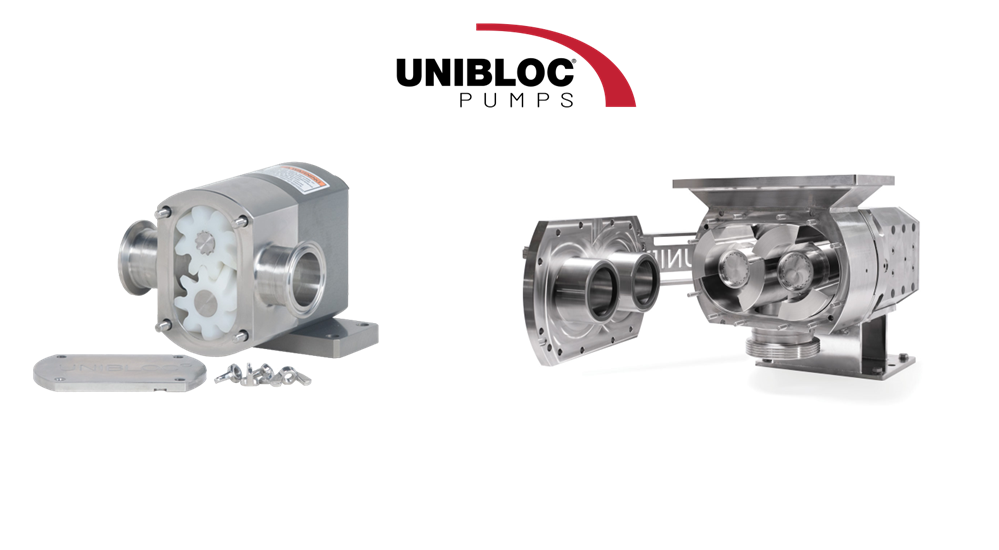

UNIBLOC Sanitary Pumps & Flow Controls

UNIBLOC Sanitary Lobe & Gear Pumps Unibloc brand pumps provide exceptional craftsmanship and an uncompromising commitment to easy maintenance and …

Read MoreFSI Gaskets EGR & EGL in Buna, Viton & EPDM Are Available. Contact us for pricing

Contact Us

Read More

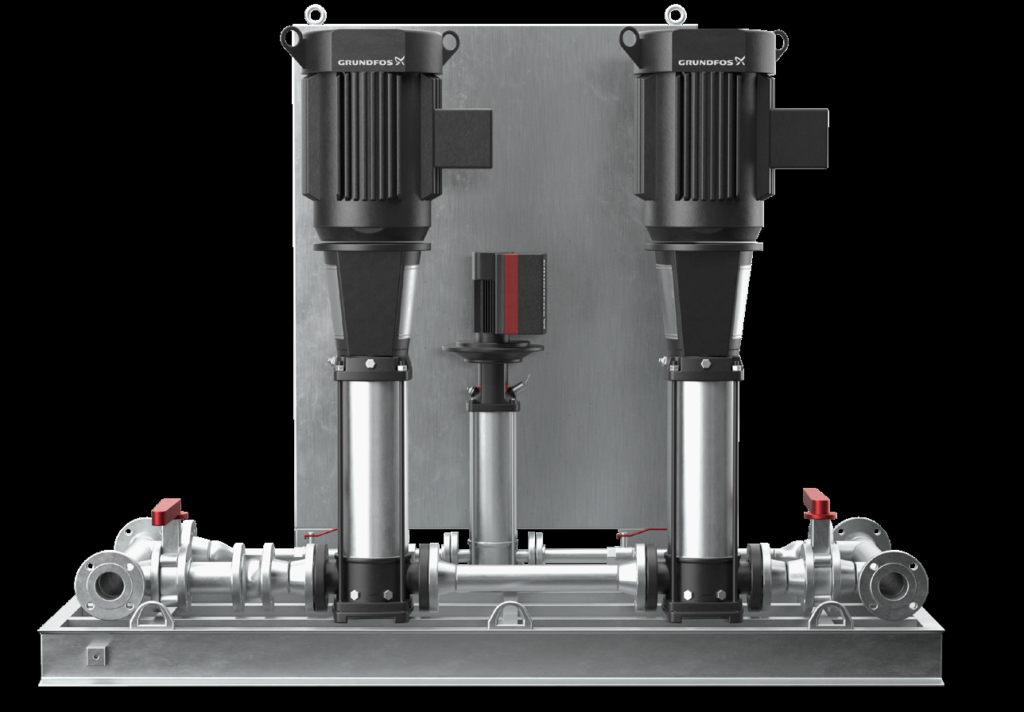

Grundfos Hydro High Pressure Packaged pump Systems

Food Processing Brochure Hydro HP Brochure Grundfos Hydro HP is a fully integrated high-pressure booster for food processing applications. System …

Read MoreForsta Self Cleaning Filters the 180 Series & 90 Series

Forsta 180 Series Self cleaning Filter The 180 Series filters offer a unique configuration of automatic self-cleaning water filters. Commonly …

Read MoreGrundfos CR 95, CR 125 & CR 155 Series needs a special tools for seal replacment

Grundfos Seal Tools Service Instructions Service Parts Special tools are required to replace the shaft seal on the CR(N)95, 125, …

Read MoreGrundfos Pump Skids – Hydro Multi E

Grundfos Pump Skids pressure booster system is an innovative boosting solution for commercial building pressure boosting, HVAC and irrigation applications. …

Read More