Standard Pump’s Sanitary Pumping Solutions

Standard Pump offers a superior selection of sanitary drum and air operated double diaphragm(AODD) pumps. Standard Pumps has offerings of 3A, Sanitary, and FDA Compliant.

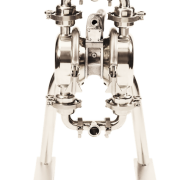

Sanitary Pumps

Standard’s Sanitary pumps are the ideal solution for food processing and pharmaceutical applications. Their sanitary AODD pumps feature highly polished 316SS components(32RA), swivel mounting and energy efficient, Tri-Clamp fittings, oil-free air valve system. Available with exclusive Fuzed PTFE or highly efficient Santoprene diaphragms. Standard’s 800SR and 800DD series drum pumps are engineered for transferring viscous food products (with abilities to transfer fluids up to 100,000 cps), pharmaceutical ingredients and cosmetic lotions from drums, totes, and kettles. SP’s Sanitary pumps are geared towards application like: pie fillings, juice concentrates, sauces, chocolates, lotions, and shampoos.

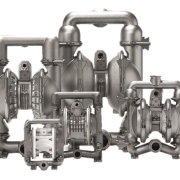

FDA Compliant Pumps

Standard’s FDA compliant pumps are specifically engineered for food and cosmetic applications and constructed with the FDA CFR Title 21 approved materials for food contact. Each pump features 316SS components, Tri-Clamp intake/discharge, and a choice of exclusive of Fuzed PTFE or highly efficient Santoprene diaphragms for the AODDS. SP’s drum pumps are light weight and portable with variable speed electric and air motors. These pumps are geared to handle applications like: juices, concentrates, personal care products, pharmaceuticals, beer, wine, and cosmetic fragrances.

3A Sanitary Pumps

Standards’ 3A Sanitary pumps are a fully documented and specifically designed for the dairy process industry. These sanitary pumps are engineered to meet the stringent safety standards set forth by the 3A Council. AODD pumps feature highly polished Stainless Steel components (32 RA), a swivel mounting stand for CIP capabilities, leak detection kit, and an energy efficient, oil-free air valve system. These pumps are designed to handle applications like: mayonnaise, yogurt, cheese, creams, milk, butter, cottage cheese, and eggs. The Drum pumps are light weight and easy to clean. Their hygienic design make them perfect for products like: juices, concentrates, personal care products, pharmaceuticals, beer, wine, and cosmetic fragrances.

BCS Ultra-Mass Series

Standard Pump’s Ultra Mass Batch Control is an innovative system designed for dosing applications. It is as simple as programming the volume or weight you want transferred and the Ultra Mass BCS will deliver a preset dose of product. The system’s components are 3A certified, ensuring the highest quality products suitable for food processing, pharmaceutical, dairy and biotech industries. the BCS features 3A (TPV) Certification, FDA Compliant Materials, Low Shear Design, Tri-Clamp Fittings, Interface Capabilities, Quick Setup Menus.