Standard drum pumps are offered in many configurations to meet the demanding applications for transferring fluids. Industrial Standard Drum Pump manufactures process pumps designed to transfer and or meter liquids, slurries and viscous products from drums, totes, tanks and kettles. Common applications include the transfer of sauces, dressings, chocolate, lotions, shampoo and creams. Our vast range of Centrifugal and Progressive Cavity pumps in conjunction with Air and Electric motor options provide an ideal solution for your sanitary application. They also offer many solutions for the industrial side of the business along with metering & batch feed standard drum pumps.

Standard drum pumps not only come in packages we do sell all of the components for example, motors, tubes & hoses.

Industrial Standard Drum Pumps

Pump Package 4 – Polypropylene With Meter

Engineered unique design allows users to safely measure and transfer corrosive liquids, Common applications include:

Applications

- Hydrochloric Acid

- Acetic Acid

- Sulfuric Acid

- Nitric Acid (20%)

Pump Package 3 – PVDF

Engineered to transfer very concentrated and extremely aggressive liquids, Common applications include:

Applications

- Sulfuric Acid – 66 Baume

- Concentrated Nitric Acid

- Hydrofluoric Acid

- Propionic Acid

Pump Package 2 – Polypropylene

Standard drum pumps Engineered to transfer corrosive Acids & Alkalies chemicals common applications.

Applications

- Hydrochloric Acid

- Acetic Acid

- Sulfuric Acid

- Nitric Acid (20%)

Pump Package 1 – CPVC

Standard drum pumps Engineered to transfer corrosive chemicals associated with the Water Treatment industry common applications.

Applications

- Sodium Hypochlorite

- Calcium Chloride

- Potassium Hydroxide

- Calcium Hydroxide

- Chlorinated Water

- Sodium Bromide

Pump Package 5 – PVDF With Meter

Engineered unique design allows operators to safely measure and transfer concentrated and very aggressive liquids, Common applications for this pump:

Applications

- Sulfuric Acid 66 baume

- Concentrated Nitric (98%)

- Hydrofluoric Acid

- Propionic Acid

Pump Package 6 – 316SS

Engineered to transfer mineral acids and suitable chemicals, Common applications include:

Applications

- Nitric Acid

- Citric Acid

Pump Package 7 – Aluminum

Engineered to transfer light oils, automotive fluids and lubricants, Common applications include:

Applications

- Light Machining Oils

- Hydraulic Fluid

- Motor Oil (Up to 30 wt.)

- Anti-Freeze

- Lubricating Oil

Pump Package 8 – 316SS Explosion Proof Air Motor

Explosion Proof Drum Pump (AIR) is a safe solution for transferring flammable/combustible liquids and meets the stringent safety requirements of the Chemical Processing Industry, Common applications include:

Applications

- Aqueous Ammonia

- Isopropyl Ether

- Alcohol

- Xylene

- Petroleum Products

- Gasoline

- Toluene

- Solvents

Pump Package 9 – 316SS Explosion Proof Electric Motor

Explosion Proof Drum Pump is a safe solution for transferring flammable/combustible liquids and meets the stringent safety requirements of the Chemical Processing Industry, Common applications include:

Applications

- Alcohol

- Solvents

- Xylene

- Isopropyl Ether

- Aqueous Ammonia

- Petroleum Products

Package 10 | EXP – Air Motor

Designed for transferring flammable/combustible liquids and meets the stringent safety requirements of the chemical processing industry.

Applications

- Alcohol

- Isopropyl Ether

- Aqueous Ammonia

- Xylene

- Petroleum Products

- Solvents

- Toluene

- Gasoline

Standard Drum Pumps Non-Corrosive Packages

Non-Corrosive Package 4-Aluminum W/Air Motor

Engineered to transfer and filter non-corrosive liquids such as machining lubricants and light oils from barrels and Tote® tanks. The integrated filter system enables the operator to safely remove contaminants from the liquid during the pumping process. Common applications for this pump:

Applications

- Light Machining Oils

- Hydraulic Fluid

- Motor Oil (up to 30 wt.)

- Anti-Freeze

- Lubricating Oil

Non-Corrosive Package 3-Aluminum

Engineered to transfer and filter non-corrosive liquids such as machining lubricants and light oils from barrels and Tote tanks. The integrated filter system enables the operator to safely remove contaminants from the liquid during the pumping process. Common applications for this pump:

Applications

- Light Machining Oils

- Hydraulic Fluid

- Motor Oil (up to 30 wt.)

- Anti-Freeze

- Lubricating Oil

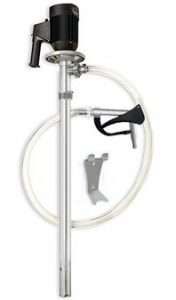

Non-Corrosive Package 2 – Aluminum, Air Motor

Engineered to transfer non-corrosive liquids such as machining lubricants and light oils from barrels and Tote® tanks. This package has been engineered to be light weight and portable while still maintaining a robust quality and high flow rate, Common applications for this pump:

Applications

- Light Machining Oils

- Motor Oil (up to 30 wt.)

- Hydraulic Fluid

- Anti-Freeze

- Lubricating Oil

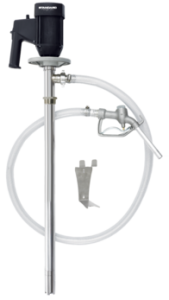

Non-Corrosive Package 1 – Aluminum

Engineered to transfer non-corrosive liquids such as machining lubricants and light oils from barrels and Tote® tanks. This package has been engineered to be light-weight and portable while still maintaining a robust quality and high flow rate, Common applications for this pump:

Applications

- Light Machining Oils

- Hydraulic Fluid

- Motor Oil (up to 30 wt.)

- Anti-Freeze

- Lubricating Oil

Standard drum pumps with batch control for industrial applications

Batch Control System | Electric Motor

Engineered to control, measure and dispense preset volumes of liquid from drums, IBC’s, plating tanks or any large storage vessel. The BCS can be used in an industry where batching, chemical packaging or dilution is required to be accurate and efficient. Simply dial in the desired volume, press ENTER and the BCS delivers a preset volume of liquid virtually hands-free.

Applications

- Chemical Packaging

- Water Treatment Chemicals

- Chemistry For Plating Tanks

- Chemical Delivery

Features

- Relay Output Signal

- PP & PVDF Materials of Construction

- 7 Pre-Set Batches

- User Friendly “In Field” Calibration

- Resettable Totalizer

- Measures: Gallons, Liters, Cubic Meters

- Turbine Paddle Wheel Design

Industrial Batch Control Systems Air Motor LOW VISCOSITY-Polypropylene & PVDF

Engineered to control, measure and dispense preset volumes of liquid from drums, IBC’s, plating tanks or any large storage vessel. The air systems are ideal for high frequency, continuous duty applications. The BCS can be used in an industry where batching, chemical packaging or dilution is required to be accurate and efficient. Simply dial in the desired volume, press ENTER and the BCS delivers a preset volume of liquid virtually hands-free.

Applications

- Chemical Packaging

- Water Treatment Chemicals

- Chemistry For Plating Tanks

- Chemical Delivery