Hydra Cell seal less pumps are available in a metallic head or non-metallic head.

Max Pressure

- Metallic Heads:

- D/G-03-X (including Kel-Cell)*: 1000 psi (70 bar)

- D/G-03-E (Kel-Cell)*: 1000 psi (70 bar)

- (non Kel-Cell): 1200 psi (83 bar)

- D/G-03-S, B, G: 1200 psi (83 bar)

- Non-Metallic Heads:

- All models: 250 psi (17 bar)

Max Temperature

- Metallic Heads: 2 50°F (121°C) – consult factory for temperatures above 160°F (71°C)

- Non-Metallic Heads: 140°F (60°C)

Max Pressure

- Non-Metallic: 250 psi (17 bar)

- Metallic: 1000 psi (70 bar)

- Slurry Duty (SD): 300 psi (21 bar)

Max Temperature

- Metallic: 250°F (121°C) – consult factory for temperatures above 160°F (71°C)

- Non-Metallic: Polypropylene: 120°F (49°C)

- Kynar, Celcon & Slurry Duty: 140°F (60°C)

- Consult factory for temperatures above 120°F (49°C)

D15 & D17 Hydra Cell Pumps

Max Pressure

- (D/G-15-E Cam only);

- 2000 psi (140 bar) @ 1450 rpm;

- 2500 psi (170 bar) @ 1150 rpm

- 1500 psi (100 bar) @ 1750 rpm

Max Temperature

- 250°F (121°C) – consult factory for temperatures above 180°F (82°C)

Max Pressure

- 1500 psi (100 bar) @ 1750 rpm

- (D/G-17-E Cam only);

- 2000 psi (138 bar) @ 1450 rpm;

- 2500 psi (172 bar) @ 1150 rpm

- Maximum Pressure: 1500 psi (103 bar)

- Maximum Flow Rate: 96 gpm (366.1 l/min)

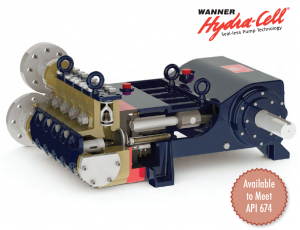

Diaphragm Pump Features

Versatile, Reliable Pumps for a Wide Range of Applications

- Compact design and double-ended shaft provide a variety of installation option

- Rugged construction for long life with minimal maintenance

- Lower energy costs than centrifugal pumps

- Hydraulically balanced diaphragms to handle high pressures with low stress

- Unique diaphragm design handles more abrasives with less wear than gear, screw or plunger pumps

- Can operate with a closed or blocked suction line and run dry indefinitely without damage, eliminating downtime and repair costs

- Low NPSH requirements allow for operation with a vacuum condition on the suction – positive suction pressure is not necessary

- Seal-less design eliminates leaks, hazards and the expense associated with seals and packing

- Maximum Pressure: 3500 psi (241 bar)

- Maximum Flow Rate: 45 gpm (170.4 l/min)

Diaphragm Pump Features

Versatile, Reliable Pumps for a Wide Range of Applications

- Pumps the full spectrum of low-to-high viscosity fluids.

- Features a seal-less design and horizontal disk check valves that enable the pump to handle abrasives and particulates that might damage or destroy other types of pumps.

- Simple, compact design reduces initial investment and lowers maintenance costs.

- Operational efficiency reduce energy costs.

- Able to run dry without damage (or additional maintenance) to the pump in case of accident or operator error.

- Minimizes maintenance and downtime because there are no seals, packing or cups to leak or replace

- Tolerates non-ideal operating conditions.

- Maximum Pressure: 5000 psi (345 bar)

- Maximum Flow Rate: 26 gpm (98.4 l/min)

Diaphragm Pump Features

Versatile, Reliable Pumps for a Wide Range of Applications

- Compact design and double-ended shaft provide a variety of installation options

- Rugged construction for long life with minimal maintenance

- Lower energy costs than centrifugal pumps

- Hydraulically balanced diaphragms to handle high pressures with low stress

- Unique diaphragm design handles more abrasives with less wear than gear, screw or plunger pumps

- Can operate with a closed or blocked suction line and run dry indefinitely without damage, eliminating downtime and repair costs

- Low NPSH requirements allow for operation with a vacuum condition on the suction – positive suction pressure is not necessary

- Seal-less design eliminates leaks, hazards and the expense associated with seals and packing

- Maximum Pressure: 144 bar (2100 psi)

- Maximum Flow Rate: 595 l/min (157 gpm)

Diaphragm Pump Features

Versatile, Reliable Pumps for a Wide Range of Applications

- Seal-less design eliminates leaks, hazards and the expense associated with seals and packing

- Low NPSH requirements allow for operation with a vacuum condition on the suction – positive suction pressure is not necessary

- Can operate with a closed or blocked suction line and run dry indefinitely without damage, eliminating downtime and repair costs

- Unique diaphragm design handles more abrasives with less wear than gear, screw or plunger pumps

- Hydraulically balanced diaphragms to handle high pressures with low stress

- Lower energy costs than centrifugal pumps

- Rugged construction for long life with minimal maintenance

- Compact design and double-ended shaft provide a variety of installation options