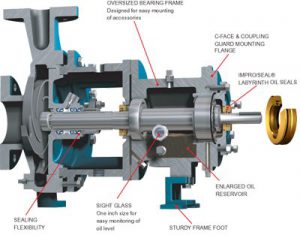

Summit Pumps – 2196 Ansi Pump

Features

- Capacities to 6000 gpm

- Heads to 730 feet

- Pressures to 375 psi

- Temperatures to 700 degrees F

- Back pull out design

- External impeller adjustment

- Heavy duty shaft & bearings

- Standard bronze Inpro® labyrinth seals

- Maximum interchangeability

- Rigid frame foot

- Fully open impeller

- Extra large oil sump

- Optional Features

- Finned-tube Oil Cooler: Can be installed in field

Multiple stuffing box cover options available.

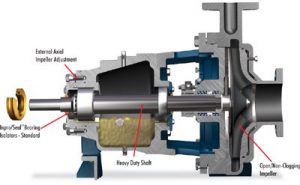

Summit Pumps – 2196R Ansi Pump

Features

- Available in 5 different sizes and a variety of materials

- Minimizes degradation of solids

- Utilizes your existing 2196 power end and ANSI bolt pattern.

- Handles fibrous and shear sensitive materials

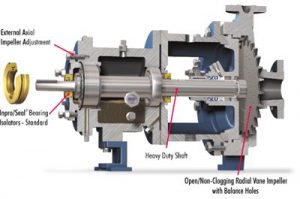

Summit Pumps – 2196LF – High pressure Low Flow

Features

- Circular non-expanding case

- Interchangeability with existing ANSI pumps

- Radial vane impeller with balance holes

Benefits

- Extended MTBF on the pump and mechanical seal

- Lower seal chamber pressure

- Lower NPSHr

- Reduced shaft vibration

Applications

- Additive Chemicals

- Batch/Continuous Chemical Reactors

- Chemical Dryers

- Chemical Process

- Condensate Service

- Evaporators

- Shower Service

- Prototype Processes

- Petro Chemical Service

- Seal Water

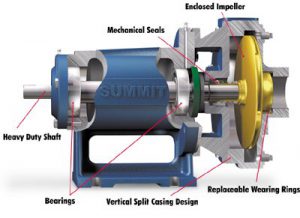

Summit Pumps – 2175 Stock/Process Pump

Features

- Double wall volute on larger sizes

- Sacrificial wear items

- Rear pull-out

- Efficient parts interchangeability

Applications

- General: Manure transfer, mine water, waste treatment

- Food: Beet and cane sugar, cane juices, fruit pulp, wet corn milling

- Steel: Cooling water, descaling, slurries, tailings

- Pulp & Paper: Cleaners, filtrate, liquor, screen rejects

Summit Pumps – Clark III Ansi Pump

Features

- Conforms to ASME B73.1M (ANSI)

- Maximum interchangeability of parts

- Semi-open reverse vane impeller

- Capacities to 5,000 GPM

- Head to 740 feet

- Pressures to 375 PSI

- Back pull out design

- Indexed bearing housing for ease and accurate impeller adjustment

Optional Features

- Finned tube oil cooler

- Open impeller design available

- Multiple rear cover options

Summit Pumps – CC & FM Close Coupled & Frame Mounted Pumps

Features

Summit CC & FM pumps are horizontal, end suction, centrifugal pumps designed for general service such as water, solvents, light oils, non-corrosive chemicals, coolants and brines. Available in capacities to 2300 GPM and heads to 200 feet, these pumps are an economical and dependable solution for your pumping needs. All flanges are 125lb ANSI B16.1 rating, NPT connections are standard on 6″ and 8″ sizes. A renewable bronze shaft sleeve is standard on cast iron pumps, and a 316SS shaft sleeve is standard on alloy pumps.

- Interchangeable Parts

Component parts, of similar sizes, are interchangeable between frame mounted and close coupled pumps. This means less spare parts inventory and fast delivery of required parts. - Frame Mounted Pump – Model FM

Frame mounted pumps are constructed with a rigid bearing frame, flexibly coupled, and mounted on a fabricated steel base with optional drip pan. Casings, adaptors, and bearing frames share mating registers for maximum interchangeability. Coupling guards meet ASME B 15.1 specifications. - Close Coupled Pump – Model CC

The close coupled pump is directly mounted to a NEMA “C” face motor, and designed to use minimal space. Motors with TEFC frames use a standard mechanical seal (JM frame), or packing(JP frame). ODP motors, and stainless steel shafts are optional.