BJM submersible pumps offers many different pumps for a variety of applications that exist. If you need a pump for general dewatering, sand sludge slurry, high temp or explosion proof (FM Rated) BJM pumps offers a pump for most applications.

BJM Dewatering Submersible

LWA BJM Series

BJM Submersible Light-Weight Agitator Dewatering Pumps. Hard Metal Submersible dewatering pumps. Designed and constructed for dewatering sand, silt, coal fines and abrasive light slurries. Chrome Iron impeller and wear plate. Hardened ductile iron agitator and volute. Built-in agitator mixes settled solids with pump water to restore sump or basin volume. Light Weight

KB Series

offers Heavy Duty Dewatering & capabilities for Light Slurry Applications: Settling Basins Retention Ponds Wash down sumps Sand & gravel dewatering Barge & tank clean out. Abrasive resistant chrome iron components. Agitator – to fluidize settled solids into suspension. Wear plate – replaceable hardened surface on the suction side where erosion would cause a loss of pump performance. Semi- open Impeller – to handle some solids.

J Series

The J-Series electric submersible pumps offer top performance and high quality for a very modest investment. The pumps are designed for long life and trouble free performance. Pumps 1/2HP and above, feature double mechanical seals which work in a separate oil chamber. Motor casings, hardware and impeller shafts are made from 304 stainless steel, with all other exposed parts made of cast iron. Oil seal ring(s) are installed above the impeller to help keep impurities and abrasives away from the mechanical seals. All pumps are equipped with an overload protection which guards against low and high amperage as well as excessive temperature.

JH Series

The JH-Series electric submersible pumps offer top performance and high quality for a very modest investment. The pumps are designed for long life and trouble free performance. Motor casings, hardware and impeller shafts are made from 304 stainless steel, with all other exposed parts made of cast iron. Pumps 1/2HP and above, feature double mechanical seals which work in a separate oil chamber. Oil seal ring(s) are installed above the impeller to help keep impurities and abrasives away from the mechanical seals. All pumps are equipped with an overload protection which guards against low and high amperage as well as excessive temperature.

R Series The Bullet

Top Discharge – allows for superior cooling of motor and provides a slim line design. Longer Power Cord – Standard 33ft. power cord on pumps ½ HP and below and 50ft. on pumps 1HP and above. 304SS Motor Housing – Superior abrasion resistance will not wear out like aluminum motor housings when pumping sandy water. Tough Pump Construction – Hardened cast iron stands up to rough handling and pumping sandy water unlike pumps with soft resin impellers or plastic exterior components*.

RX Series

Top discharge pumps pass the liquid up and around the motor before discharging. This ensures better motor cooling in low level liquid applications. RXpumps are available in one (1) and two (2) HP, in single phase and three-phase. Class F insulation and overload protection ensures a long life. RX models are delivered standard with 2” stainless NPT discharge connection.(3″ adapter available). All wear and “wet” parts such as impeller, wear-plate, oil housing, pump-housing and inner pump top are made of Cast 316 stainless material. The elastomers such as o-rings, lip seals and gaskets are made of FKM. Standard power cable is made of oil-resistant material. Special installation can be made with EPDM power-cable and elastomers. (BUNA (Nitril) also available).

Baby Series

This 12 volt battery operated submersible pump delivers up to 1,500 GPH, or up to 23 feet of head, yet weighs only 8 lbs. The Baby features 16.5′ power cable with terminal clips, corrosion resistant motor housing, 316 stainless steel shaft, and 1″ male/female discharge, 3/4″ garden hose adapter included. Perfect for emptying pipe trenches, bailing out a boat, or pumping down a flooded basement. Its non-metallic construction makes it suitable for salt water.

BJM Sand, Sludge & Slurry Pumps

KZE Series

If you need this pump fast BJM usually stocks one of each of the KZE Pumps, contact us for stock check

Sealing System – oil cooled and lubricated double mechanical seal design with SiC vs. SiC faces and Buna N elastomers. Seal chamber protected from pumpage by labyrinth rings and lipseal. Seal Minder®- leak detection probe. Bearing System – permanently lubricated upper and lower bearings with high temperature grease to extend life. Upper radial bearing is roller bearing design. Lower radial and axial thrust bearing is double row angular contact design. Impeller – Semi-open hard metal slurry type impeller capable of passing 1″ solids to accommodate heavy slurry loading. Agitator – Hard metal agitator keeps heavy solids from settling and allows them to be pumped away.

- Pump Materials of Construction – 28% high chrome iron wear parts (volute, impeller, wear plate).

- 403SS shaft and impeller key

- 304SS hardware & fasteners

- Cast iron motor housing

- High chrome iron agitator

HAZ Series

The HAZ pump is the first permissible slurry pump with an agitator. Designed to resist abrasive wear that causes loss of pump performance. Less down time, less maintenence and less repairs. Outlasts rubber lined and regular cast iron pumps.

- Permissible heavy duty hard metal agitator submersible slurry dewatering pump

- Designed and constructed for abrasive coal slurries

- High-Chrome iron impeller, wear plate and agitator

- Hardened ductile iron volute

- Built-in agitator mixes settled solids with pump water to restore sump or basin volume.

KZN Series

KZN Heavy Duty Submersible Slurry Pumps with agitator is the choice of industries that face the most difficult pumping: Lime slurries • Mill scale • Coal runoff sumps • Wash down sumps • Ash transfer • Tailings ponds • Slag pits • Food wastes • Silt removal • Sand & gravel dewatering • Barge & tank cleanout

EVERY KZN slurry pump is constructed with the following abrasive resistant 28% chrome iron (600 Brinell, 57 Rockwell C) components.

- TOP 3 REASONS WHY YOU SHOULD CHOOSE THE KZN

- Agitator – to fluidize settled solids into a slurry.

- Wear plate – replaceable hardened surface on the suction side where erosion would cause a loss of pump performance.

- Semi- open Impeller – to handle abrasive solid concentrations as high as 70% by weight.

KZNR Series

KZNR HI-HARD™ SEVERE DUTY SLURRY PUMP – with agitator. The KZNR HI-HARD™ pumps have proprietary process hardened ductile iron volutes.

It is the choice of industries that face the most difficult pumping:

Lime slurries • Mill scale • Coal runoff sumps • Wash down sumps • Ash transfer • Tailings ponds • Slag pits • Food wastes • Silt removal • Sand & gravel dewatering • Barge & tank cleanout

TOP 3 REASONS WHY YOU SHOULD CHOOSE THE KZNR HI-HARD™…

EVERY KZNR HI-HARD™ slurry pump is constructed with the following abrasive resistant chrome iron components.

- Agitator – to fluidize settled solids into a slurry.

- Wear plate – replaceable hardened surface on the suction side where erosion would cause a loss of pump performance.

- Semi- open Impeller – to handle abrasive solid concentrations as high as 70% by weight.

KB Series

Used for settling basins, retention ponds, wash down sumps, sand & gravel dewatering, barge & tank cleanout, and more.

KBF Series

KBF Series high temperature submersible pump offers heavy duty dewatering and capabilities for light slurry applications including:

- Food waste

- Wash down sumps

- Sand & gravel dewatering

- Barge & tank cleanout

KBHF Series

- Abrasive resistant chrome iron components:

- Agitator – Fluidizes settled solids into suspension.

- Wear plate – Replaceable hardened surface on the suction side where erosion would cause a loss of pump performance.

- Semi-open impeller to handle some solids.

- Every KBHF pump model is protected by:

- Class R motor insulation and built-in amperage (FLA) and temperature overload protection.

- Double mechanical seals – SiC/SiC – FKM lower and carbon ceramic FKM upper in a separate oil-filled seal chamber.

- Heavy duty lip seal – Additional protection for the mechanical seals.

- Stainless steel shaft and shaft sleeve – Save on shaft wear due to abrasives and corrosion.

- The KBHF Series are top discharge pumps:

- KBHF Series pumps are utility pumps and frequently dragged from one site to another. The KBHF doesn’t have a side discharge connection that can break off or be damaged as it is pulled and pushed into place.

- Top discharge pumps are cooled by pumped liquid – The KBHF pumps can pump a sump or pit down to within inches of the bottom. A side discharge pump without a cooling jacket must stay submerged to avoid overheating, leaving as much as three feet of unpumped slurry.

- Top discharge means slim – even the largest model with a 13.5 inch “waistline” will fit down a manhole with a hose attached. High-chrome agitator helps keep solids suspended in liquid and helps prevent pump from clogging.

- High-chrome agitator helps keep solids suspended in liquid and helps prevent pump from clogging.

- Specifications dependent on model and may change without notice.

KZN-HYD Series

KZN-HYD Series is the hydraulic version of the very popular KZN Series Heavy Duty Submersible Slurry Pump with agitator. Ideal for applications were electric power is not available, or variable speed is needed for the application. It is the choice of industries that face the most difficult pumping:

Sewage By-Pass • Lime slurries • Mill scale • Coal runoff sumps • Wash down sumps • Ash transfer • Tailings ponds • Slag pits • Food wastes • Silt removal • Sand & gravel dewatering • Barge & tank cleanout

EVERY KZN-HYD slurry pump is constructed with the following abrasive resistant chrome iron components.

- Agitator – to fluidize settled solids into a slurry.

- Wear plate – replaceable hardened surface on the suction side where erosion would cause a loss of pump performance.

- Semi- open Impeller – to handle abrasive solid concentrations as high as 70% by weight.

KHD Series

- Long service life in rugged applications provided by hard metal components, including a high chrome iron impeller and ductile iron wear plate and pump volute.

- Oil-lubricated, double mechanical seal design featuring early warning seal failure protection circuit to ensure the longest pump and motor life.

- Solids handling capabilities up to ¼”.

- Power to match your needs with ranges from 15 HP to 100 HP.

- Superior motor life with Class F motor insulation.

BJM Solids Handling Pumps, Submersible Shredder Pumps (Cutter Pumps), Vortex Pumps, Trash Pumps, Vane Pumps.

SKG submersible pump series

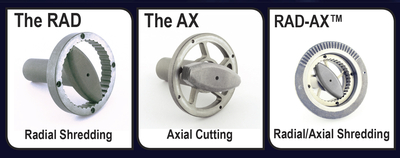

Featuring patent-pending RAD-AX™ Dual Shredding Technology, the SKG Series is designed to obliterate flushable wipes and other difficult solids in municipal and industrial wastewater applications. Items previously considered difficult or near impossible to pump are effectively handled through the innovative design of the SKG. The robust construction prevents downtime and reduces maintenance for longer life. Top features include:

- RAD-AX™ Dual Shredding Technology (Patent-pending) featuring radial and axial shredding elements.

- All shredding elements constructed of hardened 440C Stainless Steel with a Rockwell hardness of 55C plus.

- Shredding System efficiency to alleviate potentially high surge load to the motor.

- Efficient, high solids passage impeller and volute design, coupled to a high torque 4-pole motor. (2, 3, & 5 HP)

- Oil-lubricated Double Mechanical Seals and separate lip seal.

- Heavy Duty SOOW power and Seal Minder® cable – for early warning moisture detection.

The hardened impeller and plate materials provide maximum wear resistance for long service life. Hardened cast iron construction stands up to rough handling and pumping gritty water.

Winding protection and (NEMA) Class F motor insulation allow motor temperatures to rise 239°F, superior to pumps with Class A and B insulation. An automatic thermal switch turns the pump motor off if the temperature and/or amp draw rises too high. When the motor cools the switch will automatically reset and the pump will turn back on.

SK submersible pump series

![]() The Shredder (SK) pumps leave solids slightly larger than if passed through a grinder pump. The shredding action is caused by using a cutting impeller with a Tungsten Carbide Tip, against a “spiral” shaped diffuser plate.

The Shredder (SK) pumps leave solids slightly larger than if passed through a grinder pump. The shredding action is caused by using a cutting impeller with a Tungsten Carbide Tip, against a “spiral” shaped diffuser plate.

- Longer Power Cord – Standard 33ft. power.

- 304SS Motor Housing – Superior abrasion resistance will not wear out like aluminum motor housings when pumping sandy water.

- Three Seal Motor Protection – Motor is protected by double mechanical seals. Lower seal made of silicon carbide/silicon carbide and upper seal is made of carbon/ceramic. An additional lip seal has been installed above the impeller, to help prevent abrasives such as dirt, silt or sand, from entering into the seal chamber.

- More Motor Protection – Winding protection and (NEMA) Class F motor insulation allows motor temperature to raise to 230°F, superior to pumps with Class A and B insulation. Automatic switch turns pump motor off if temperature and/or amp draw raises too high. When the motor cools the switch will automatically reset and the pump will turn back on.

- Tough Pump Construction – Hardened cast iron stands up to rough handling and pumping sandy water unlike pumps with soft resin impellers or plastic exterior components.

SV submersible pump series

The SV-pumps are equipped with Vortex impellers, undoubtedly the best non-clog impellers ever invented for the handling of mud, raw sewage, viscous liquids, rags, wood chips and other solids. They pass solid up to 90% of pump outlet diameter.

- Longer Power Cord – Standard 33ft. power cord on pumps ½ HP and below and 50ft. on pumps 1HP and above.

- 304SS Motor Housing – Superior abrasion resistance will not wear out like aluminum motor housings when pumping sandy water.

- Three Seal Motor Protection – Motor is protected by double mechanical seals. Lower seal made of silicon carbide/silicon carbide and upper seal is made of carbon/ceramic. An additional lip seal has been installed above the impeller, to help prevent abrasives such as dirt, silt or sand, from entering into the seal chamber.

- More Motor Protection – Winding protection and (NEMA) Class F motor insulation allows motor temperature to raise to 230°F, superior to pumps with Class A and B insulation. Automatic switch turns pump motor off if temperature and/or amp draw raises too high. When the motor cools the switch will automatically reset and the pump will turn back on.

- Tough Pump Construction – Hardened cast iron stands up to rough handling and pumping sandy water unlike pumps with soft resin impellers or plastic exterior components.

S submersible pump series

![]() The S-pumps have non-clog, single vane impellers designed for high volume and lift performance.

The S-pumps have non-clog, single vane impellers designed for high volume and lift performance.

- Longer Power Cord – Standard 33ft. power cord on pumps ½ HP and below and 50ft. on pumps 1HP and above.

- 304SS Motor Housing – Superior abrasion resistance will not wear out like aluminum motor housings when pumping sandy water.

- Three Seal Motor Protection – Motor is protected by double mechanical seals. Lower seal made of silicon carbide/silicon carbide and upper seal is made of carbon/ceramic. An additional lip seal has been installed above the impeller, to help prevent abrasives such as dirt, silt or sand, from entering into the seal chamber.

- More Motor Protection – Winding protection and (NEMA) Class F motor insulation allows motor temperature to raise to 230°F, superior to pumps with Class A and B insulation. Automatic switch turns pump motor off if temperature and/or amp draw raises too high. When the motor cools the switch will automatically reset and the pump will turn back on.

- Tough Pump Construction – Hardened cast iron stands up to rough handling and pumping sandy water unlike pumps with soft resin impellers or plastic exterior components.

BJM Submersibles 316 Stainless Steel Submersible Chemical Resistant Pumps, Transfer Pumps, Dewatering Pumps and Shredder Pumps

SX submersibles pump series

![]() The SX-pumps have non-clog, single vane impellers designed for high volume and lift performance.

The SX-pumps have non-clog, single vane impellers designed for high volume and lift performance.

All wear and “wet” parts such as impeller, wear-plate, oil housing, pump-housing and inner pump top are made of Cast 316 stainless material. The elastomers such as o-rings, lip seals and gaskets are made of FKM. Standard power cable is made of oil-resistant material. Special installationcan be made with EPDM power-cable and elastomers. (BUNA-N also available).

- All parts exposed to pumped liquids are made of 316 Stainless Steel.

- Elastomers are made of FKM.

- Longer Power Cord – Standard 33ft. power cord.

- Three Seal Motor Protection – Motor is protected by double mechanical seals. Lower seal made of silicon carbide/silicon carbide and upper seal is made of carbon/ceramic. An additional lip seal has been installed above the impeller, to help prevent abrasives such as dirt, silt or sand, from entering into the seal chamber.

- More Motor Protection – Winding protection and (NEMA) Class F motor insulation allows motor temperature to raise to 230°F, superior to pumps with Class A and B insulation. Automatic switch turns pump motor off if temperature and/or amp draw raises too high. When the motor cools the switch will automatically reset and the pump will turn back on.

SKX submersible pump series

![]() Side discharge and non-clog single vane impellers for the passing of solids while delivering high volume of liquids through 2 – 6 inch pipe.

Side discharge and non-clog single vane impellers for the passing of solids while delivering high volume of liquids through 2 – 6 inch pipe.

The Shredder (SKX) type pumps leave solids slightly larger than if passed through a grinder pump. The shredding action is cause by using a cutting impeller with a Tungsten Carbide Tip, against a “spiral” shaped diffuser plate.

The SKX -pumps have non-clog, single vane impellers designed for high volume and lift performance. All wear and “wet” parts such as impeller, wear-plate, oil housing, pump-housing and inner pump top are made of Cast 316 stainless material. The elastomers such as o-rings, lip seals and gaskets are made of FKM . Standard power cable is made of oil-resistant material. Special installation can be made with EPDM power-cable and elastomers. (BUNA (Nitril) also available).

- All parts exposed to pumped liquids are made of 316 Stainless Steel.

- Elastomers are made of FKM.

- Longer Power Cord – Standard 33ft. power cord.

- Three Seal Motor Protection – Motor is protected by double mechanical seals. Lower seal made of silicon carbide/silicon carbide and upper seal is made of carbon/ceramic. An additional lip seal has been installed above the impeller, to help prevent abrasives such as dirt, silt or sand, from entering into the seal chamber.

- More Motor Protection – Winding protection and (NEMA) Class F motor insulation allows motor temperature to raise to 230°F, superior to pumps with Class A and B insulation. Automatic switch turns pump motor off if temperature and/or amp draw raises too high. When the motor cools the switch will automatically reset and the pump will turn back on.

Each pump is tested at factory, both for performance as well as safety. Level controls and level control systems are available.

JXH submersible pump series

Side discharge submersibles are typically used in sump applications where the liquid level can be controlled and where the pumps are partially submerged when in operation. The JXH models are designed for general high head pumping purposes where the passing or shredding of larger solids is not required.

JXH pumps are available in size 2 to 10 HP. Single-phase versions are 2 HP, 230V. Dual mechanical seals with the lower seal made of highly wear resistant Sic/Sic, for less downtime and long life.

All “wet parts” are of highest quality 316 stainless steel. Wear parts are made of Cast material. The 2, 3 and 5 HP JXH pumps are made with Precision Cast Parts (also referred to as Investment Castings), the same quality that is used in aircraft and space vehicles due to it’s superior density and strength. Other models are manufactured with sand cast parts. Elastomers such as gaskets and o-rings are made of FKM.

Standard power cable is made of oil resistant quality, which works very well in most environments. EPDM quality cable and elastomers as well as BUNA elastomers are available on special order.

- All parts exposed to pumped liquids are made of 316 Stainless Steel.

- Elastomers are made of FKM.

- Longer Power Cord – Standard 33ft. power cord.

- Three Seal Motor Protection – Motor is protected by double mechanical seals. Lower seal made of silicon carbide/silicon carbide and upper seal is made of carbon/ceramic. An additional lip seal has been installed above the impeller, to help prevent abrasives such as dirt, silt or sand, from entering into the seal chamber.

- More Motor Protection – Winding protection and (NEMA) Class F motor insulation allows motor temperature to raise to 230°F, superior to pumps with Class A and B insulation. Automatic switch turns pump motor off if temperature and/or amp draw raises too high. When the motor cools the switch will automatically reset and the pump will turn back on.

- JX55HSS and JX75HSS MODELS – The 7.5 and 10 HP models are designed with an outer sleeve on the impeller shaft. Two oil seal rings, upper and lower, rides on this replaceable shaft which prevents the formation of grooves on the impeller shaft itself.

- TWO PUMPS IN ONE – Most sizes can be converted to a high head version by merely changing the impeller and the suction plate. Other brands often require major changes to achieve different heads or volumes.

JX submersible pump series

Side discharge submersibles are typically used in sump applications where the liquid level can be controlled and where the pumps are partially submerged when in operation. The JX models are designed for general pumping purposes where the passing or shredding of larger solids is not required.

JX pumps are available in size 0.5 to 10 HP. Single-phase versions are from 0.5 to 2 HP 50 Hz models can be ordered at the same low price as 60Hz. Dual mechanical seals with the lower seal made of highly wear resistant Sic/Sic, for less downtime and long life.

All “wet parts” are of highest quality 316 stainless steel. Wear parts are made of Cast material. The 0.5 to 5 H.P. JX pumps are made with PrecisionCast Parts(also referred to as Investment Castings), the same quality that is used in aircraft and space vehicles due to it’s superior density and strength. Other models are manufactured with sand cast parts.

Elastomers such as gaskets and o-rings are made of FKM.

Standard power cable is made of oil resistant quality, which works very well in most environments. EPDM quality cable and elastomers as well as BUNA elastomers are available on special order.

- All parts exposed to pumped liquids are made of 316 Stainless Steel.

- Elastomers are made of FKM.

- Longer Power Cord – Standard 33ft. power cord.

- Three Seal Motor Protection – Motor is protected by double mechanical seals. Lower seal made of silicon carbide/silicon carbide and upper seal is made of carbon/ceramic. An additional lip seal has been installed above the impeller, to help prevent abrasives such as dirt, silt or sand, from entering into the seal chamber.

- More Motor Protection – Winding protection and (NEMA) Class F motor insulation allows motor temperature to raise to 230°F, superior to pumps with Class A and B insulation. Automatic switch turns pump motor off if temperature and/or amp draw raises too high. When the motor cools the switch will automatically reset and the pump will turn back on.

- TWO PUMPS IN ONE – Most sizes can be converted to a high head version by merely changing the impeller and the suction plate. Other brands often require major changes to achieve different heads or volumes.

RX submersible pump series

Top discharge 316 cast stainless steel pumps.

Top discharge pumps pass the liquid up and around the motor before discharging. This ensures better motor cooling in low level liquid applications.

RX pumps are available in one (1) and two (2) HP, in single phase and three-phase. Class F insulation and overload protection ensures a long life. RX models are delivered standard with 2” stainless NPT discharge connection.(3″ adapter available).

All wear and “wet” parts such as impeller, wear-plate, oil housing, pump-housing and inner pump top are made of Cast 316 stainless material. The elastomers such as o-rings, lip seals and gaskets are made of FKM. Standard power cable is made of oil-resistant material. Special installation can be made with EPDM power-cable and elastomers. (BUNA (Nitril) also available).

- All parts exposed to pumped liquids are made of 316 Stainless Steel.

- Elastomers are made of FKM.

- Longer Power Cord – Standard 33ft. power cord.

- Three Seal Motor Protection – Motor is protected by double mechanical seals. Lower seal made of silicon carbide/silicon carbide and upper seal is made of carbon/ceramic. An additional lip seal has been installed above the impeller, to help prevent abrasives such as dirt, silt or sand, from entering into the seal chamber.

- More Motor Protection – Winding protection and (NEMA) Class F motor insulation allows motor temperature to raise to 230°F, superior to pumps with Class A and B insulation. Automatic switch turns pump motor off if temperature and/or amp draw raises too high. When the motor cools the switch will automatically reset and the pump will turn back on.

Perfecta submersible pump

Ideal for pumping everything from contaminated, dirty water, corrosive liquids to light dewatering.

Used in the following U.S. industries:

Metal Plating, Salt Mining, Plumbing, Marine, Agriculture, Aquaculture, Chemical, Rental, Utilities and Fire Departments.

- Virtually unbreakable

- Compact and lightweight. Only 13.5 Lbs.

- Never rusts. Excellent resistance against acids, alkalis.

- Two discharge ports. 1 1/4″ inside threaded connection and one 1 1/2″ tapered hose connection delivered with each pump.

- Thermal breaker incorporated in motor windings shuts off power before over-heating occurs due to locked rotor or long periods of running dry (150°C). For permanent installation temperature should not to exceed 135°F. For intermittent use submerge less than 20 min. in 195°F maximum.

The GF32-9 and IGF32-9 comes equipped with a fully automatic on/off level switch as standard. The pump is easily installed in a sump. The Perfecta® Pump for safeguarding vaults, emptying tanks or pumping out ponds. The unique dual port design virtually eliminates kinks in your hose; use vertical port for deep/narrow places or use the horizontal port for shallow/wide applications.

The GF32-9 and IGF32-9 comes equipped with a fully automatic on/off level switch as standard. The pump is easily installed in a sump. The Perfecta® Pump for safeguarding vaults, emptying tanks or pumping out ponds. The unique dual port design virtually eliminates kinks in your hose; use vertical port for deep/narrow places or use the horizontal port for shallow/wide applications.

Not for use in flammable liquids! Consult chemical resistance chart for compatibility between pump materials and liquid before operating pump

BJM submersible Fahrenheit pumps are great when you need a pump that can handle high temps up to 200 degree Fahrenheit & corrosive or non corrosive fluid. Materials are 316ss or cast iron.

JXF submersible pump 316ss

DEWATERING PUMP

Side discharge submersibles are typically used in sump applications where the liquid level can be controlled and where the pumps are partially submerged when in operation. The JXF models are designed for general pumping purposes where the passing or shredding of larger solids is not required.

JXF pumps are available in size 1 to 10 HP – 3 Phase. Dual mechanical seals with the lower seal made of highly wear resistant silicon carbide against silicon carbide, for less downtime and long life.

All “wet parts” are of highest quality 316 stainless steel. Wear parts are made of Cast material. JXF pumps 1HP – 5HP are made with Precision Cast Parts(also referred to as Investment Castings), the same quality that is used in aircraft and space vehicles due to it’s superior density and strength. Other models are manufactured with sand cast parts.

All elastomers (gaskets and o-rings) are made of FKM.

- All parts exposed to pumped liquids are made of 316 Stainless Steel.

- Elastomers are made of FKM.

- Longer Power Cord – Standard 33ft. power cord.

- Three Seal Motor Protection – Motor is protected by double mechanical seals. Lower seal made of silicon carbide/silicon carbide and upper seal is made of carbon/ceramic. An additional lip seal has been installed above the impeller, to help prevent abrasives such as dirt, silt or sand, from entering into the seal chamber.

- More Motor Protection – Winding protection and (NEMA) Class R motor insulation with a thermal cut out switch that will allow the stator to have a winding temperature of up to 300 degrees F (150 C), superior to pumps with Class A and B insulation.

JF submersible pump cast iron

DEWATERING PUMP

The JF-Series electric submersible pumps offer top performance and high quality for a very modest investment. The pumps are designed for long life and trouble free performance.

- TWO PUMPS IN ONE

Most JF-Series pumps can quickly be converted from High Volume to High Head (or vice-versa) by merely changing the impeller and the suction plate. Other brands often require major changes to achieve different heads or volumes. - Motor casings, hardware and impeller shafts are made from 304 stainless steel, with all other exposed parts made of cast iron.

- All

pumps feature double mechanical seals which work in a separate oil chamber.

pumps feature double mechanical seals which work in a separate oil chamber. - Oil seal ring(s) are installed above the impeller to help keep impurities and abrasives away from the mechanical seals.

- Optional Seal Minder can be installed to help monitor the integrity of the mechanical seal system.

JXHF submersible pump 316ss

HIGH HEAD DEWATERING PUMP

Side discharge submersibles are typically used in sump applications where the liquid level can be controlled and where the pumps are partially submerged when in operation. The JXHF models are designed for general high head pumping purposes where the passing or shredding of larger solids is not required.

JXHF pumps are available in size 2 to 10 HP.

Dual mechanical seals with the lower seal made of highly wear resistant silicon carbide/silicon carbide, for less downtime and long life.

All “wet parts” are of highest quality 316 stainless steel. Wear parts are made of Cast material. The 1, 2, 3 and 5 HP JXHF pumps are made with Precision Cast Parts (also referred to as Investment Castings), the same quality that is used in aircraft and space vehicles due to it’s superior density and strength. Other models are manufactured with sand cast parts.

Elastomers such as gaskets and o-rings are made of FKM.

Standard power cable is made of oil resistant quality, which works very well in most environments. EPDM quality cable and elastomers as well as BUNA elastomers are available on special order.

- All parts exposed to pumped liquids are made of 316 Stainless Steel.

- Elastomers are made of FKM.

- Longer Power Cord – Standard 33ft. power cord.

- Three Seal Motor Protection – Motor is protected by double mechanical seals. Lower seal made of silicon carbide/silicon carbide and upper seal is made of carbon/ceramic. An additional lip seal has been installed above the impeller, to help prevent abrasives such as dirt, silt or sand, from entering into the seal chamber.

- More Motor Protection – Winding protection and (NEMA) Class R motor insulation with a thermal cut out switch that will allow the stator to have a winding temperature of up to 300 degrees F (150 C), superior to pumps with Class A and B insulation.

JXF submersible pump cast iron

DEWATERING PUMP

The JHF-Series electric submersible pumps offer top performance and high quality for a very modest investment. The pumps are designed for long life and trouble free performance.

- TWO PUMPS IN ONE

Most JF-Series pumps can quickly be converted from High Volume to High Head (or vice-versa) by merely changing the impeller and the suction plate. Other brands often require major changes to achieve different heads or volumes. - Motor casings, hardware and impeller shafts are made from 304 stainless steel, with all other exposed parts made of cast iron.

- All Fahrenheit™ pumps feature double mechanical seals which work in a separate oil chamber.

- Oil seal ring(s) are installed above the impeller to help keep impurities and abrasives away from the mechanical seals.

SXF submersible pump 316ss

SOLIDS HANDLING PUMP

316 Cast Stainless Steel Pumps with Single Vane or Double Vane Impellers for Municipal, Industrial and Agricultural Waste-Water.

Side discharge and non-clog single vane impellers for the passing of solids while delivering high volume of liquid.

![]() The SXF-pumps have non-clog, single vane impellers designed for high volume and lift performance.

The SXF-pumps have non-clog, single vane impellers designed for high volume and lift performance.

All wear and “wet” parts such as impeller, wear-plate, oil housing, pump-housing and inner pump top are made of Cast 316 stainless material. The elastomers such as o-rings, lip seals and gaskets are made of FMK. •All parts exposed to pumped liquids are made of 316 Stainless Steel.

- Elastomers are made of FMK.

- Longer Power Cord – Standard 33ft. power cord.

- Three Seal Motor Protection – Motor is protected by double mechanical seals. Lower seal made of silicon carbide/silicon carbide and upper seal is made of carbon/ceramic. An additional lip seal has been installed above the impeller, to help prevent abrasives such as dirt, silt or sand, from entering into the seal chamber.

- More Motor Protection – Winding protection and (NEMA) Class R motor insulation with a thermal cut out switch that will allow the stator to have a winding temperature of up to 300 degrees F (150 C), superior to pumps with Class A and B insulation.

SF submersible pump cast iron

SOLIDS HANDLING PUMP

Electric Submersible Pumps with Single Vane or Double Vane Impellers for Municipal, Industrial and Agricultural Waste-Water

![]() The SF-pumps have non-clog, single vane or double vane impellers designed for high volume and lift performance.

The SF-pumps have non-clog, single vane or double vane impellers designed for high volume and lift performance.

- Longer Power Cord – Standard 33ft. power cord.

- 304SS Motor Housing – Superior abrasion resistance will not wear out like aluminum motor housings when pumping sandy water.

- Three Seal Motor Protection – Motor is protected by double mechanical seals. Lower seal made of silicon carbide/silicon carbide and upper seal is made of carbon/ceramic. An additional lip seal has been installed above the impeller, to help prevent abrasives such as dirt, silt or sand, from entering into the seal chamber.

- More Motor Protection – Winding protection and (NEMA) Class R motor insulation with a thermal cut out switch that will allow the stator to have a winding temperature of up to 300 degrees F (150 C), superior to pumps with Class A and B insulation.

- Tough Pump Construction – Hardened cast iron stands up to rough handling and pumping sandy water unlike pumps with soft resin impellers or plastic exterior components.

SKXF submersible pump 316ss

SHREDDER PUMP316 Cast Stainless Steel Pumps with Shredder Action Impellers for Municipal, Industrial and Agricultural Waste-Water.Side discharge and non-clog single vane or double vane impellers for the passing of solids while delivering high volume of liquids.

![]() The Shredder (SKXF) pumps leave solids slightly larger than if passed through a grinder pump. The shredding action is caused by using a cutting impeller with a Tungsten Carbide Tip, against a “spiral” shaped diffuser plate.

The Shredder (SKXF) pumps leave solids slightly larger than if passed through a grinder pump. The shredding action is caused by using a cutting impeller with a Tungsten Carbide Tip, against a “spiral” shaped diffuser plate.

All wear and “wet” parts such as impeller, wear-plate, oil housing, pump-housing and inner pump top are made of Cast 316 stainless material. The elastomers such as o-rings, lip seals and gaskets are made of FMK.

- All parts exposed to pumped liquids are made of 316 Stainless Steel.

- Elastomers are made of FMK.

- Longer Power Cord – Standard 33ft. power cord.

- Three Seal Motor Protection – Motor is protected by double mechanical seals. Lower seal made of silicon carbide/silicon carbide and upper seal is made of carbon/ceramic. An additional lip seal has been installed above the impeller, to help prevent abrasives such as dirt, silt or sand, from entering into the seal chamber.

- More Motor Protection – Winding protection and (NEMA) Class R motor insulation with a thermal cut out switch that will allow the stator to have a winding temperature of up to 300 degrees F (150C), superior to pumps with Class A and B insulation.

Each pump is tested at factory, both for performance as well as safety. Level controls and level control systems are available.

SKF submersible pump cast iron

SHREDDER PUMP

![]() The Shredder (SKF) pumps leave solids slightly larger than if passed through a grinder pump. The shredding action is caused by using a cutting impeller with a Tungsten Carbide Tip, against a “spiral” shaped diffuser plate.

The Shredder (SKF) pumps leave solids slightly larger than if passed through a grinder pump. The shredding action is caused by using a cutting impeller with a Tungsten Carbide Tip, against a “spiral” shaped diffuser plate.

- Longer Power Cord – Standard 33ft. power.

- 304SS Motor Housing – Superior abrasion resistance will not wear out like aluminum motor housings when pumping sandy water.

- Three Seal Motor Protection – Motor is protected by double mechanical seals. Lower seal made of silicon carbide/silicon carbide and upper seal is made of carbon/ceramic. An additional lip seal has been installed above the impeller, to help prevent abrasives such as dirt, silt or sand, from entering into the seal chamber.

- More Motor Protection – Winding protection and (NEMA) Class R motor insulation with a thermal cut out switch that will allow the stator to have a winding temperature of up to 300 degrees F (150 C), superior to pumps with Class A and B insulation.

- Tough Pump Construction – Hardened cast iron stands up to rough handling and pumping sandy water unlike pumps with soft resin impellers or plastic exterior components.

Each pump is tested at factory, both for performance as well as safety. Level controls and level control systems are available.

KZNF submersible pump cast iron

SLURRY PUMP

KZNF Heavy Duty Submersible Slurry Pumps with agitator is the choice of industries that face the most difficult pumping:

Lime slurries • Mill scale • Coal runoff sumps • Wash down sumps • Ash transfer • Tailings ponds • Slag pits • Food wastes • Silt removal • Sand & gravel dewatering • Barge & tank cleanout

TOP 3 REASONS WHY YOU SHOULD CHOOSE THE KZNF…

- EVERY KZNF slurry pump is constructed with the following abrasive resistant 28% chrome iron (600 Brinell, 57 Rockwell C) components;

- Agitator – to fluidize settled solids into a slurry.

- Wear plate – replaceable hardened surface on the suction side where erosion would cause a loss of pump performance.

- Semi- open Impeller – to handle abrasive solid concentrations as high as 70% by weight.

- EVERY KZNF slurry pump model is protected by;

- Class R motor insulation – and built in amperage ( FLA ) and temperature overload protection.

- Double silicon carbide mechanical seals – in a separate oil filled seal chamber.

- Heavy Duty Lip Seal – additional protection for the mechanical seals.Stainless steel shaft and shaft sleeve – saves on shaft wear due to abrasives and corrosion.

- Pump volutes cast from hardened Ductile Iron – 300 Brinnell hardness; twice as abrasive resistant as standard ductile iron.

- EVERY KZNF is a top discharge pump;

- KZNF heavy duty slurry pumps are utility pumps; frequently dragged from one site to another. The KZNF doesn’t have a side discharge connection that can break off or be damaged as it is pulled and pushed into place.

- Top discharge pumps are cooled by pumped liquid – The KZNF slurry pumps can pump a sump or pit down to within “inches” of the bottom. A side discharge pump without a cooling jacket must stay submerged to avoid overheating, leaving as much as 3 feet of un-pumped slurry.

- Top discharge means “SLIM” – even the largest model with a 22.75 inch “waistline” will fit down a manhole with a hose attached.

- The KZNF’s hardened ductile iron volutes – cast with extra thick walls at the point where pumped slurry enters the discharge.

High-Chrome Agitator helps keep solids suspended in liquid and helps prevent pump from clogging.

High-Chrome Agitator helps keep solids suspended in liquid and helps prevent pump from clogging.

KZNRF submersible pump cast iron

KZNRF HI-HARD™ SEVERE DUTY SLURRY PUMP – with agitator.

The KZNRF HI-HARD™ pumps have proprietary process hardened ductile iron volutes.

It is the choice of industries that face the most difficult pumping:

Lime slurries • Mill scale • Coal runoff sumps • Wash down sumps • Ash transfer • Tailings ponds • Slag pits • Food wastes • Silt removal • Sand & gravel dewatering • Barge & tank cleanout

TOP 3 REASONS WHY YOU SHOULD CHOOSE THE KZNRF HI-HARD™…

- EVERY KZNRF HI-HARD™ slurry pump is constructed with the following abrasive resistant chrome iron components;

- Agitator – to fluidize settled solids into a slurry.

- Wear plate – replaceable hardened surface on the suction side where erosion would cause a loss of pump performance.

- Semi- open Impeller – to handle abrasive solid concentrations as high as 70% by weight.

- EVERY KZNRF HI-HARD™ slurry pump model is protected by;

- Class R motor insulation – and built in amperage ( FLA ) and temperature overload protection.

- Double silicon carbide mechanical seals – in a separate oil filled seal chamber.

- Heavy Duty Lip Seal – additional protection for the mechanical seals.

- Stainless steel shaft and shaft sleeve – saves on shaft wear due to abrasives and corrosion.

- Pump volutes cast from hardened Ductile Iron – Proprietary plasma treated for extra hardness & long life.

- EVERY KZNRF HI-HARD™ is a top discharge pump;

- KZNRF heavy duty slurry pumps are utility pumps; frequently dragged from one site to another. The KZNRF doesn’t have a side discharge connection that can break off or be damaged as it is pulled and pushed into place.

- Top discharge pumps are cooled by pumped liquid – The KZNRF slurry pumps can pump a sump or pit down to within “inches” of the bottom. A side discharge pump without a cooling jacket must stay submerged to avoid overheating, leaving as much as 3 feet of un-pumped slurry.

- Top discharge means “SLIM” – even the largest model with a 22.75 inch “waistline” will fit down a manhole with a hose attached.

- The KZNRF HI-HARD™ pumps have proprietary process hardened ductile iron volutes – cast with extra thick walls at the point where pumped slurry enters the discharge.

High-Chrome Agitator helps keep solids suspended in liquid and helps prevent pump from clogging.

High-Chrome Agitator helps keep solids suspended in liquid and helps prevent pump from clogging.

BJM explosion proof submersible pumps with an FM rating class 1, DIV 1, groups C & D locations. BJM explosion proof pumps are available in cast iron or 316ss they can handle a slurry mix or shredding.

XPKZN XP submersible pump cast iron

SLURRY PUMPS

The XP-KZN pump is a heavy duty explosion proof slurry pump with an agitator. Designed to resist abrasive wear that causes loss of pump performance. Less down time, less maintenance and less repairs. Outlasts rubber lined and regular cast iron pumps.

- Top discharge, slim line design

- Explosion proof, FM approved, C/US approved(Class I,Div. I,Group C&D)

- Designed and constructed for abrasive slurries

- High-Chrome iron impeller, wear plate and agitator

- Hardened ductile iron volute

- Built-in agitator mixes settled solids with pump water to restore sump or basin volume.

XPSKX XP submersible pump 316ss

SHREDDER PUMPS

316 Cast Stainless Steel – Explosion Proof Electric Submersible Pumps with Shredder Action Impellers for use in Class I, Division 1, Groups C & D Hazardous Locations

XP-SKX Series

![]() Shredder (SKX & XP-SKX) pumps leave solids slightly larger than if passed through a grinder pump. The shredding action is caused by using a cutting impeller with a Tungsten Carbide Tip, against a “spiral” shaped diffuser plate. XP-SKX -pumps have non-clog, single vane impellers designed for high volume and lift performance. All wear and “wet” parts such as impeller, wear-plate, oil housing, pump-housing and inner pump top are made of Cast 316 stainless material. The elastomers such as o-rings, lip seals and gaskets are made of FKM . Standard power cable is made of oil-resistant material. Special installation can be made with EPDM power-cable and elastomers. (BUNA (Nitril) also available).

Shredder (SKX & XP-SKX) pumps leave solids slightly larger than if passed through a grinder pump. The shredding action is caused by using a cutting impeller with a Tungsten Carbide Tip, against a “spiral” shaped diffuser plate. XP-SKX -pumps have non-clog, single vane impellers designed for high volume and lift performance. All wear and “wet” parts such as impeller, wear-plate, oil housing, pump-housing and inner pump top are made of Cast 316 stainless material. The elastomers such as o-rings, lip seals and gaskets are made of FKM . Standard power cable is made of oil-resistant material. Special installation can be made with EPDM power-cable and elastomers. (BUNA (Nitril) also available).

FM Approved motor for use in Class I, Division 1, Groups C & D hazardous locations. Available in 208, 230, 460 or 575 Volt 60Hz. Contact factory for 50Hz availability.

- All parts exposed to pumped liquids are made of 316 Stainless Steel.

- Three Seal Motor Protection – Motor is protected by two independent mechanical seals. Lower seal made of silicon carbide/silicon carbide and upper seal is made of carbon/ceramic. An additional lip seal has been installed to help prevent abrasives such as dirt, silt or sand, from entering into the seal chamber. Standard elastomers are Buna N (FKM optional).

- More Motor Protection – Air filled motor with winding protection and (NEMA) Class F motor insulation. Seal leakage detector(s) in seal chamber offers early warning should water enter the chamber.

- Epoxy Coated Motor Housing – Superior two part epoxy to protect the motor from exposure to the surrounding liquid.

- Tough Pump Construction – Hardened cast iron stands up to rough handling and pumping sandy water unlike pumps with soft resin impellers or plastic exterior components.

- Longer Power Cord – Standard 50ft. power.

XPSK XP submersible pumps

SHREDDER PUMPS

Explosion Proof Electric Submersible Pumps with Shredder Action Impellers for use in Class 1, Division 1, Groups C & D Hazardous Locations

![]() XP-SK Series

XP-SK Series

The Shredder (SK & XP-SK) pumps leave solids slightly larger than if passed through a grinder pump. The shredding action is caused by using a cutting impeller with a Tungsten Carbide Tip, against a “spiral” shaped diffuser plate.

- Shredder Pump – with FM Approved motor for use in Class I, Division 1, Groups C & D hazardous locations. Available in 208, 230, 460 or 575 Volt 60Hz. Contact factory for 50Hz availability.

- Longer Power Cord – Standard 33ft. power.

- Epoxy Coated Motor Housing – Superior two part epoxy to protect the motor from exposure to the surrounding liquid.

- Three Seal Motor Protection – Motor is protected by two independent mechanical seals. Lower seal made of silicon carbide/silicon carbide and upper seal is made of carbon/ceramic. An additional lip seal has been installed to help prevent abrasives such as dirt, silt or sand, from entering into the seal chamber. Standard elastomers are Buna N (FKM optional).

- More Motor Protection – Air filled motor with winding protection and (NEMA) Class F motor insulation. Seal leakage detector(s) in seal chamber offers early warning should water enter the chamber.

- Tough Pump Construction – Hardened cast iron stands up to rough handling and pumping sandy water unlike pumps with soft resin impellers or plastic exterior components.

XP-JX Series

316 cast stainless steel explosion proof electric submersible pumps for use in Class I, Division 1, Groups C & D Hazardous Locations

The XP-JX Series are corrosion resistant, FM-rated explosion proof submersible pumps designed for top performance. All “wet” parts such as impeller and wear plate are made of cast 316 stainless material. The elastomers such as o-rings, lip seals and gaskets are made of FKM. Standard power cable is made of oil-resistant material. Special installation can be made with EPDM power-cable and elastomers. (BUNA (Nitril) also available).

FM-approved motor for use in Class I, Division 1, Groups C & D hazardous locations. Available in 208, 230, 460 or 575 Volt 60Hz. Contact factory for 50Hz availability. High head models available.